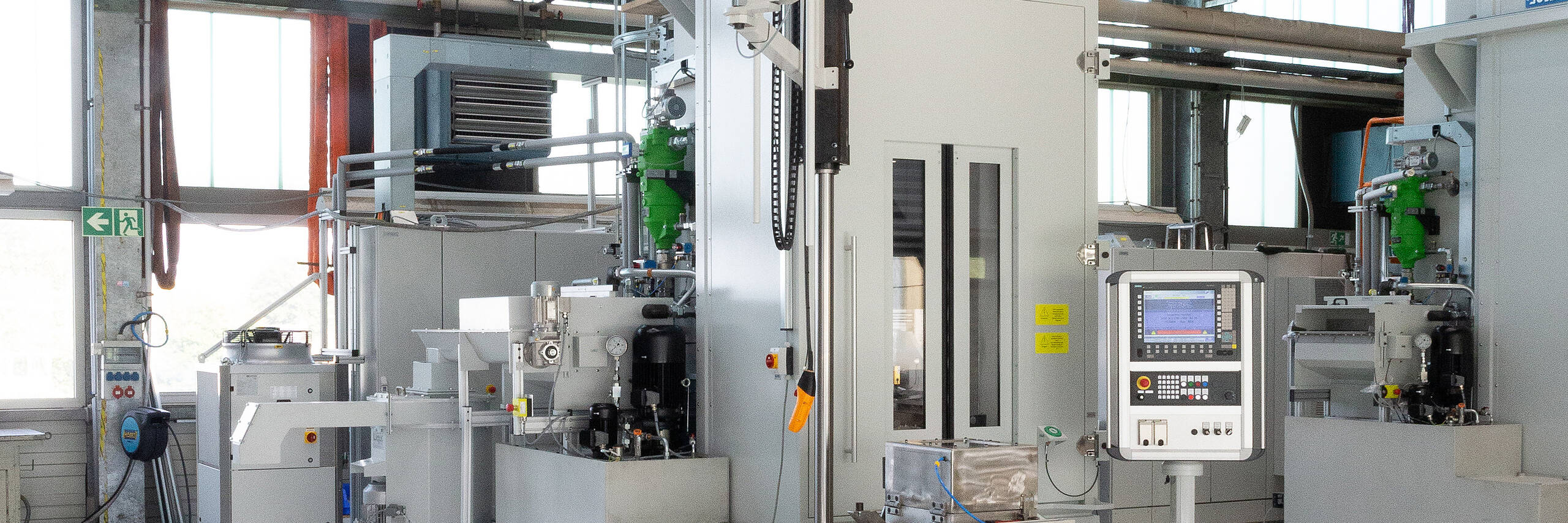

Internal broaching machines

Internal broaching machines - for soft or hard broaching

At FORST, we configure the internal broaching machines in our RISH series individually for every customer, whether for soft or hard broaching, as well as for wet or dry processes. The right internal broaching tools are of course provided too.

For wet or dry broaching

Our experienced team of process experts can help you figure out which process will deliver the quality, efficiency and clever use of resources that you need.

The choice of wet or dry broaching depends on a variety of economic and ecological factors.

We at FORST understand the challenges you face. We support you from the design of your machine right up to commissioning, and provide additional services throughout operation.

For soft or hard broaching

FORST internal broaching machines for straight broaching (such as for broaching internal gearing on hardened workpieces) are designed for hard broaching. This achieves a high surface quality and dimensional tolerance, and avoids costly reworking processes.

Technical data

Broaching force:

80 kN - 1.200 kN (Weichräumen)

63 kN - 1.600 kN (Harträumen)

Stroke:

500 - 2.800 mm

Broaching speed:

1 m/min - 24 m/min (soft broaching)

1 m/min - 60 m/min (hard broaching)

Tool length:

bis 3.000 mm

How you benefit from internal broaching machines from FORST:

- Variable number of broaching stations

- High stability, rigidity and durability

- High precision throughout the machine’s entire service life

- Efficient use of resources and reduced process costs through recovery of the broaching oil with chip centrifuges, along with cleaning stations for broached workpieces, for example