Turbine disc broaching machines

Turbine disc broaching machines for horizontal and vertical broaching

We offer external broaching machines for horizontal broaching (RAWX series) and vertical broaching (RASX series) on turbine discs. The RAWX series in particular boasts an innovative design that makes it much lighter and more compact. What makes FORST turbine disc broaching machines special is the way that the workpiece moves along the tool. Although our turbine disc broaching machines are technically part of our range of custom machines, they have long become standard.

RAWX series - high productivity in a compact package

We have successfully created turbine disc broaching machines for the aviation and energy sectors on numerous occasions. Users are impressed by their outstanding productivity despite their compact size, along with the high precision and rigidity typical of all FORST machines. To get the best results, use these machines together with the FORST broaching tools that are right for your process.

The turbine disc broaching machines in our RAWX series have proven themselves for years in aviation applications, but are also used for broaching smaller turbines in the energy sector.

How you benefit from the turbine disc broaching machines in the RAWX series

- Compact design requires little space

- No pit necessary, as the machine weight is half that of a conventional design

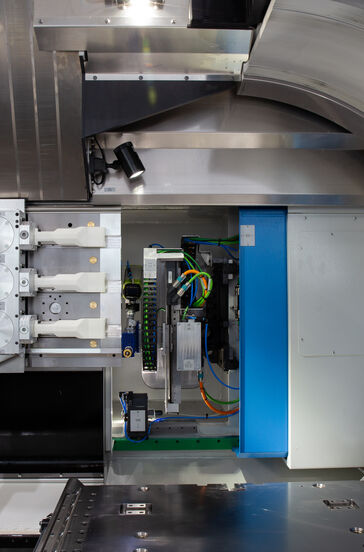

- Completely enclosed (avoids oil mist)

- Excellent accessibility

- Process monitoring (broaching force)

- Integrated measurement system (quality assurance, reduced cycle times)

- Automated workpiece holder change – autonomous series process (upstream tool buffer capacity)

- Automatic tool cassette change

Technical data

RAWX series

Broaching force:

80 kN - 160 kN

Stroke:

5.400 mm

Broaching speed:

max. 40 m/min

Maximum disc diameter:

1.000/1.200 mm

RASX series

Broaching turbine discs for the energy sector places incredible demands on the mechanisms of the broaching machine. Our RASX series is specially designed to respond to these challenges. Thanks to their high rigidity, they can achieve excellent precision despite high broaching forces. They can even process workpieces weighing up to 15,000 kg with ease. Our RASX broaching machines have a dynamic drive that enables short process times and high productivity.

Your benefits with RASX-series broaching machines for turbine discs

- Reduced height

- Robust design

- High dynamic performance

- Reliable and stable process control

- Efficient tool cleaning

- Automatic tool change

- Reduced environmental impact

- Minimal noise emissions

Technical Data

RASX series

Broaching force:

160 kN - 320 kN

Stroke:

4.700 mm

Broaching speed: 1,5 - 60 m/min

Maximum disc diameter:

2.700 mm

In this video, you can see how the compact, high-performance machines in our RAWX series efficiently broach turbine discs through a real-life example: