26. Jun 25

Broaching vs. Power Skiving

Which process is best in large series production?

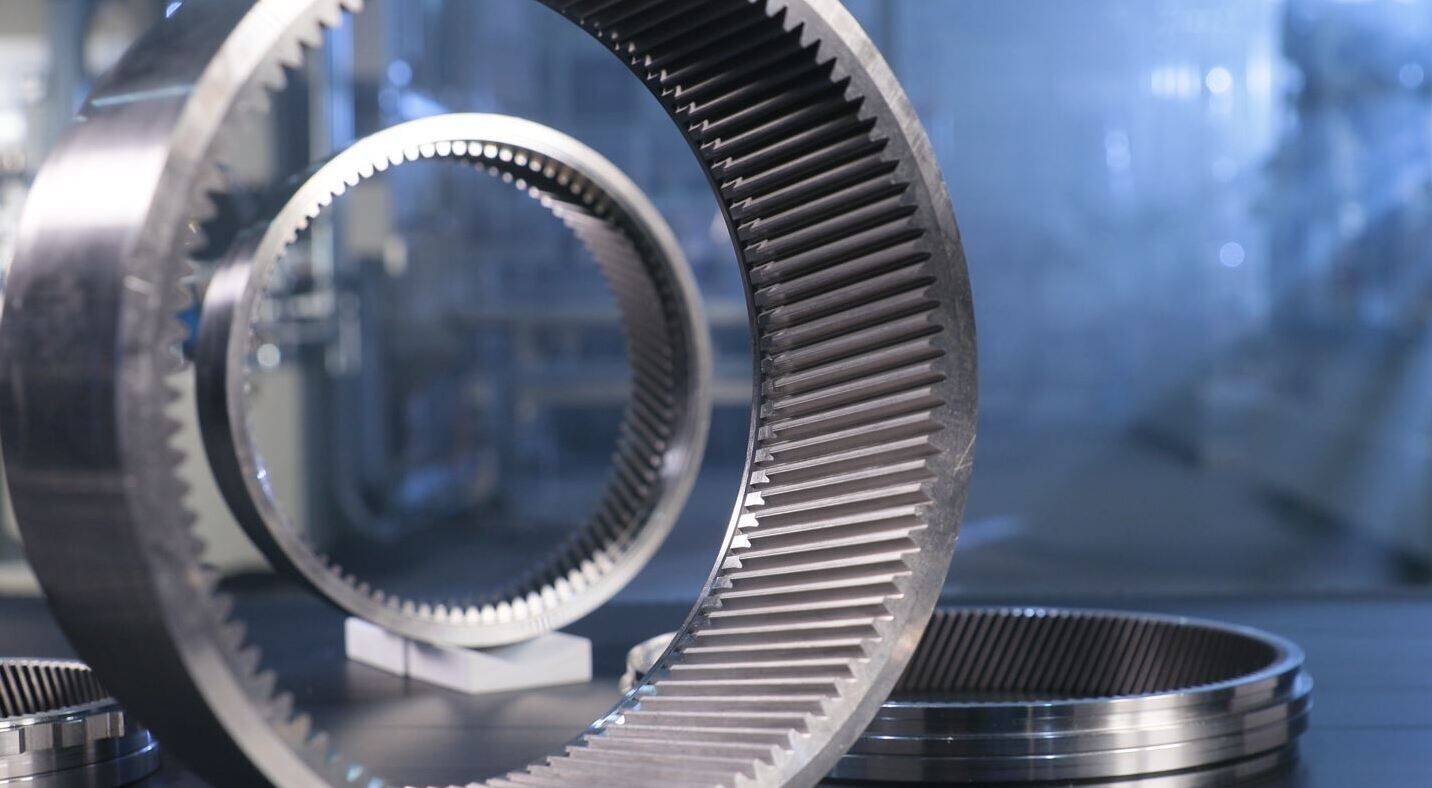

In the world of machining, there are all kinds of processes for manufacturing high-precision workpieces. Specialists looking to create internal or external gearing are frequently faced with the choice between broaching and power skiving. Both processes have their own strengths. Find out in this article why broaching is the superior process for high-volume series production.

Fewer broaching machines, lower investment costs

Broaching machines are more expensive than machines for power skiving, but this is only half the story. At high production volumes, a single broaching machine can deliver the same output as two to five power skiving machines, depending on conditions. As a result, the costs for broaching machinery do not weigh as much on the bottom line as at first glance. In fact, for a fair comparison, we must also consider the greater space requirements and multiple automation systems needed for multiple power skiving machines.

Lower costs per workpiece

Another factor in broaching’s favor are the costs per workpiece, which comprise the costs of the tools and their sharpening cycle or service life. In broaching, these costs fall as production volumes increase. In power skiving, by contrast, the workpiece costs remain unchanged. This makes broaching a more economical process for large series by comparison. One cost factor in power skiving that is often overlooked are the shorter test intervals caused by shorter tool lives. As SPC parts are measured more frequently, they require greater measurement capacities, leading to additional costs and/or bottlenecks.

| Broaching | (Power-) Skiving | |

|---|---|---|

| Machinery Costs | - - | + |

| Cycle Time | + + + | - - |

| Costs per workpiece | + + | - |

| Influence of personnel on quality | + + + | - |

| Adjustment effort | + + | - - |

Simple process stability, less complexity

Broaching is without doubt the process of choice for businesses that continuously produce large series. The smaller number of required machines, lower workpiece costs and simpler machine operation make broaching a cost-effective and highly stable process, particularly at high production volumes. In series production, broaching delivers proven efficiency and long-term profitability.

High precision and repeatability

Broaching delivers a degree of precision that is vital in mass component production in particular. The broaching machines’ high stability and accuracy enable consistent production of workpieces with minimal tolerances. This is decisive when it comes to achieving quality and durability.

Conclusion

Broaching is without doubt the process of choice for businesses that continuously produce large series. The smaller number of required machines, lower workpiece costs and simpler machine operation make broaching a cost-effective and highly stable process, particularly at high production volumes. In series production, broaching delivers proven efficiency and long-term profitability.